- INTRODUCTION

In this global era, competition is an inevitable issue for every company in this world, either manufacture company or non-manufacture company. Every company has rapid growth along with the rapid industrial evolution. This matter triggers a tight competition that should or will have to be faced by each company in the world. It means that the company will race to ingratiate the customers for buying their products. One of the crucial things one company should insist in is preserving quality in their mass production continuously by improving some innovation based on the customers’ appetite and what’s going on in the market. Moreover, nowadays, consideration of the customers before buying one product are not the same as the past. Perhaps what be the main consideration for the buyers in purchasing something is quality. But, for now, not only does the quality play on the stage, but the price, product design, brand, availability, and its value as well. But what makes them buy twice, or over and over is the quality. It suggests that quality is one of the crucial things that have to be taken care about by the company to be maintained and upgraded. That’s why to maintain the existed quality, one company need quality management that handled for controlling the quality, whether it’s going down and should be upgraded or repaired or not. In quality control itself concerning two crucial instances, those are monitoring the process of production and taking correction action.

Quality control is very substantial for one company in their production process, seeing that increasingly fierce competition in the global, especially for Coca-Cola Company in grapping their toughest rival, Pepsi.co. It’s very important for Cola-Cola Company as the leader in beverage company to control their quality of their products. Coca-Cola Company succeeds to dominate the national and international market, both from small businesses to large restaurant. Coca-Cola Company produces some soft drink products such as Coca-Cola, Sprite, Fanta, and Fresh Tea, packaged in glass bottles with different size. In this paper, we will discuss Coca-Cola. In controlling their products’ quality, Coca-Cola Company sets their products’ quality standard, involving sugar levels, CO2 levels, bottle cleanliness, bottle condition, and even the taste should meet the requirements of the standards that have been set by the company. Can’t be denied that one company like Coca-Cola, of course, will face some quality problems of their products in consequence of human fault, machine error or the lack of controlling that then might cause the products’ defects. One of the consequences if Coca-Cola Company makes faulty in their quality control is the customers will lose their trustworthy towards those products and switch to the other company’s products. The customers may move to Pepsi.co, in view of the competition between both rivals.

- Formulation of Problems

- Why the Coca-Cola Company needs to do quality control management?

- What kind of problem that usually faced by Coca-Cola Company related to their Coca-Cola’s quality and how they resolve it?

- How is the Coca-Cola’s quality management practices in Coca-Cola Company?

- Research Purposes

- To know the importance of quality control management of Coca-Cola Company to survive in tight global competition, especially in the beverage industry.

- To determine the Coca-Cola’s quality problems of Coca-Cola Company and their strategies in solving those problems.

- Determine the Coca-Cola’s quality management practices in Coca-Cola Company.

- LITERATURE REVIEW

A measurement of how much or how far one product could meet the requirements or specification that had been established by the company named quality (Iswanto, 2013). (Heizer, 2016) divided the definitions of quality into several categories, that are user based, manufacturing based, and product based. In user based, quality could be seen from the eyes which looking, preferred by the marketers and also customers. In manufacturing based, the production managers believed that quality was when the products were in accordance with the set standards. In products based, quality was the variable that could be measured and should be precise.

(Heizer, 2016) determined seven tools that usually used in quality management, including Cause-Effect Chart or known as Fishbone Chart and also Pareto chart. Pareto charts showed that the employees should concern in minimising the defects of the products. It also showed the majority factors that occurred the most that needed to be tackled. That’s why Pareto Chart was very useful in determining the target of the company (Perzyk, 2007). While, fishbone diagram was a diagram that evaluated the causes of a problem with the sub-causes that would help the company to reveal all indication of business related problems (American Society for Quality, 2005). (Public Health Infrastructure, 2008) mentioned that one of the weaknesses of fishbone chart was it didn’t explain the specific of problem causes in the appropriate order. It only explained the causes as the outline.

(Rampersad, 2010) stated that quality management was really importance for a company in creating continuous improvement of their business. To him, sustainability of a company was impossible without the existence of the constants improvement of the company. (Aized, 2012) believed that if a company was able to manage their good quality, it would lead them to higher profits. He suggested that all companies should implement a good quality management system in their company so that they could sustain and reached their organisational goals (Aized, 2012). Every company had their own quality management system which in practice might be different from one company to another company as well (Ab Wahid & Corner, 2009).

- ANALYSIS

- The Importance of Quality Control Management

The Coca-Cola Company is one of the multinational company in the world. Since the first stand, one of Coca-Cola Company’s dreams is being the leader in beverage company in the world. International business is a definite thing passed by Coca-Cola Company because they directly interact with the international. It means that the competitors of Coca-Cola Company are not only from one country but hundreds country around the world. So, that’s crucial for a multinational company such as Coca-Cola Company to really focus on their quality management to attract the customers to keep buying their products and do not switch to another company just because of the quality of the products they produce. Quality is not only about something that can be felt, seen, measured, or how the company manages it, but quality denote something that should be preferred to be concerned about by the company in making an operational decision. A company through good quality of the products they produce indirectly will contribute in improving the loyalty of the customers, also the provocateur customers. Provocateur customers here mean the customers who will always persuade the others to buys the same products as theirs, either in the positive or negative way. If in a positive way, this kind of customers will help Coca-Cola in getting more and more customers then because what they share is a personal judgement about one product, their good experience related to the products. In contrast, in a negative way, the customers will share a bad experience related to the product. It will harm the company, admitting that people nowadays tend to believe what the others’ saying easily without looking for further information. Bad news spread faster than the good ones. It’ll then affect to the image of the company and people will have bad perspective towards Coca-Cola Company’s products then, including Coca-Cola.

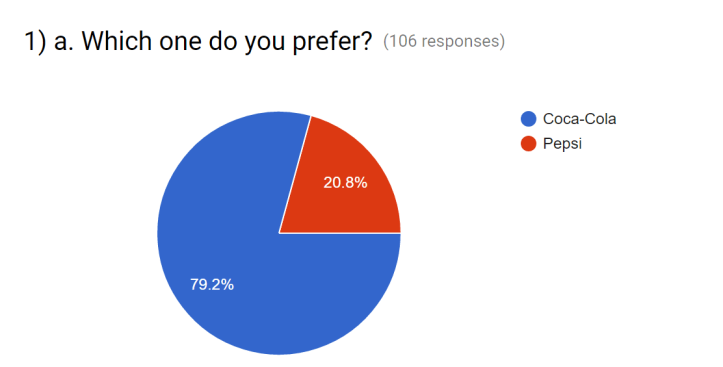

Customers will assume that the quality of Coca-Cola is bad, and they move to another brand such as Pepsi by Pepsi.co, Coca-Cola’s rival. The research shows the results 84 of 106 respondents prefers Coca-Cola instead of Pepsi, for different reasons. There are some who prefer the favour of Coca-Cola, advertisement of Coca-Cola is more aggressive than Pepsi, the brand of Coca-Cola, the quality of Coca-Cola itself that always same from the first time they established, and so on.

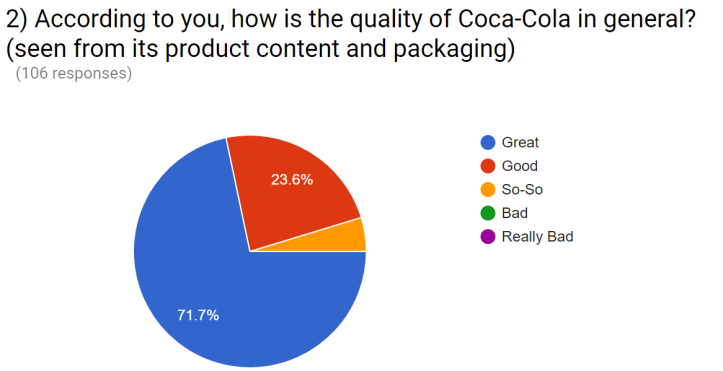

Mostly agree that Coca-Cola provides great or at least good quality for their customers. It shows the successful of Coca-Cola to keep providing good quality for their customers.

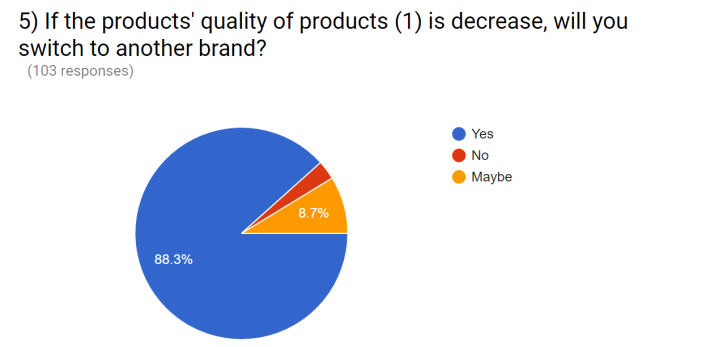

Almost all of them (91 persons) stated that they will move to another brand if the related brand they prefer provides bad quality of the product, either Coca-Cola or Pepsi.

This data shows that the quality management of one company, especially Coca-Cola Company is really important to hold their existed customers to keep purchasing the products and not move to another brand.

- The Defect of Coca-Cola And Coca-Cola Company’s in Resolving Those Problems

Quality management of Coca-Cola includes two types, that are the quality of the content and the quality of packaging.

In 2014, Coca-Cola lost their sales 1% caused by negative issues of products quality befell The Coca-Cola Company, especially on their carbonated soft drinks, like Coca-Cola. The loss of 1% seems like a small number, but the decrease in their sales volume would make Cola-Cola Company quandary in meeting their long-term targets – 3% – 4% increase in sales volume and 5% – 6% increase in profits per year. The decrease itself was caused by negative issues related to the content of their products especially acidity and carbonation contained therein. In the 1980s, Coca-Cola removed the content of wine and replaced the cocaine with the non-narcotic coca leaves, whereas beforehand, Coca-Cola used as a medicine because of the content of wine, cocaine, and sodium that considered can cope with the digestive problems, launched a gas exhaust and relief of pain. Along with the rise in prices of sugar, Coca-Cola began using sugar from a chemical process known as fructose and no longer use the coca leaf. Since then, health issues related to Coca-Cola was increasingly going up. Moreover, various studies showed that soda and fructose were the main source of high calories that could aggravate obesity, diabetes and if it is consumed in the long-term period, it could cause osteoporosis. CSE (Centre for Science and Environment) of India alleged some carbonated drinks produced by some beverage company, including Coca-Cola Company contained toxic lindane and DDT, which could contribute to cancer and immune system disorders.

But, Coca-Cola Company did not remain silent in facing those negative issues related to the quality of their products’ content. They ran some strategies in returning their company image, such through they announcement of their global commitment in terms of products, education on the packaging and marketing activities, to help the campaign in the fight against obesity. Dr. Maxime Buyckx, Principal Scientist of The Coca-Cola Company in Jakarta defended that they had provided not only carbonated drinks but also a selection of drinks with low or no calories to all customers. They also provided information about the number of calories in front of each pack transparently. They also confessed that they had run a responsible marketing activity, with no advertising to children under 12 years old. Besides, they also had another strategy through programs they created to boost active, healthy, fit and inspire a positive lifestyle, related to physical activities, and also education activities, such as.

- Football tournament among Senior High School students to fight getting Coca-Cola trophy.

- Being FIFA World Cup sponsorship.

- In Indonesia, they had Coca-Cola Club Coke Kicks and in cooperation with the program of PBSI, “Angkat Raketmu”.

- Site of The Beverage Institute for Health and Wellnes, beverageinstitute.org/indonesia/ that provided information and articles about the drinks, lifestyle and health based on proved scientific based research.

- Health campaign, named “Indonesia SeGar (Sehat and Bugar)” with the objective of encouraging people healthy and active lifestyle.

- Coca-Cola made an animated film that emphasised the movement or activity in everyday life.

- Coca-Cola with the Perhimpunan Dokter Spesialis Kedokteran Olahraga (PDSKO) launched the “Exercise Is Medicine (EIM)”, an educational program that’s for the doctors and health care providers such as Personal Trainer (PT) to include physical exercise as part of the treatment for their patients.

By involving the third parties, they had a final goal so that their products could still be sold in the market and changed the perspective of the customers as the result of the negative issues. Ratri Wuryandari as Sustainability Communication Manager of PT. Coca-Cola Indonesia said that the objectives of the programs they created were communicating a message that Coca-Cola could be a part of the healthy lifestyle if it’s supported by healthy physical activities, and don’t judge a sick person by the products they consumed. By these strategies, they could be sustained until now.

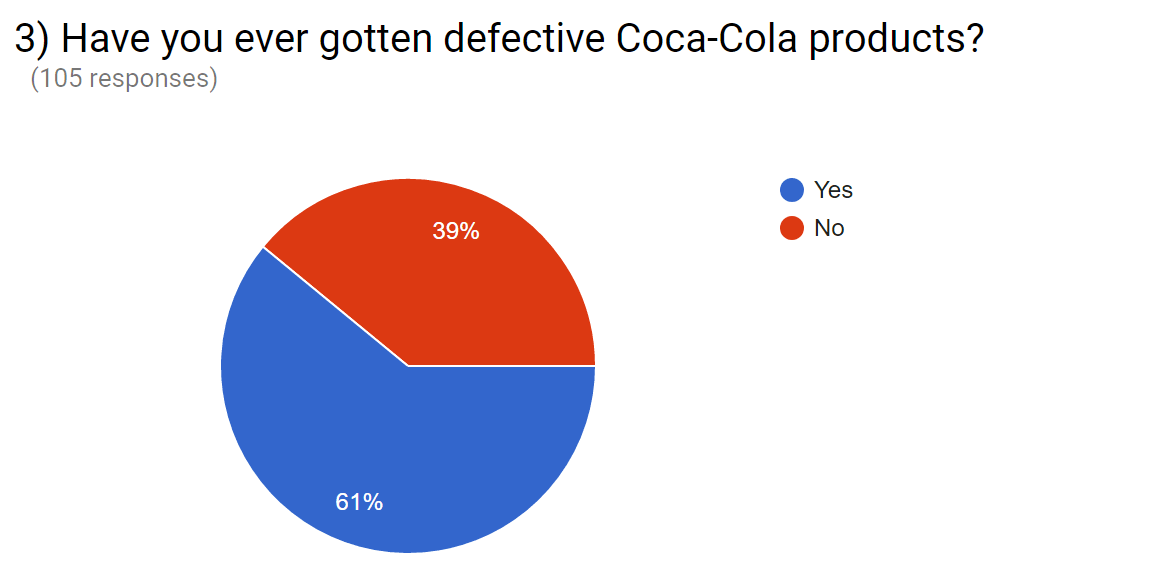

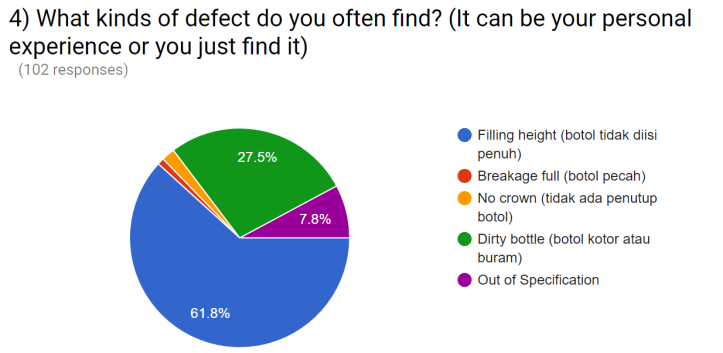

Besides, Coca-Cola often faced problems related to their packaging quality of their products. Many of their customers complained about the products defect. From the data below, we can see that 64 of 105 respondents ever gotten the defective Coca-Cola.

For instance, the bottle was not fully filled, dirty bottles, no crown or bottle cover, out of specification, spilling beverage and so on. Those defects could be caused by several factors such as human negligence and also machines error. The frequent problem that usually occurred in producing Coca-Cola was filling height.

The Coca-Cola Company had vent cube for each volume of their products. Longer the vent cube, the filling would be less and vice versa. Sometimes, the operators were wrong in adjusting the vent cube and stuffing volume should be. It caused the filling of Coca-Cola was not in accordance with the standards. The operators also often been negligent in checking the condition of glycol. It caused cooling process could not be run maximally so that CO2 didn’t absorb and caused foaming. Then, they were negligent because sometimes they were not aware if there were dirty bottles passed the inspection. In filling process, it would cause foaming which raised the volume of the product was not in accordance with the specified standards. Besides, the filling height was not in accordance with the standard was caused by spilling beverage.

The Coca-Cola Company had vent cube for each volume of their products. Longer the vent cube, the filling would be less and vice versa. Sometimes, the operators were wrong in adjusting the vent cube and stuffing volume should be. It caused the filling of Coca-Cola was not in accordance with the standards. The operators also often been negligent in checking the condition of glycol. It caused cooling process could not be run maximally so that CO2 didn’t absorb and caused foaming. Then, they were negligent because sometimes they were not aware if there were dirty bottles passed the inspection. In filling process, it would cause foaming which raised the volume of the product was not in accordance with the specified standards. Besides, the filling height was not in accordance with the standard was caused by spilling beverage.

To avoid the problems reoccurs, Coca-Cola Company tighter the requirement in recruiting employees that aimed to get qualified employees who were responsible for their jobs and conscientious with every single error that would cause the products defect. They also created some training for their employees in how they were supposed to run their jobs. Besides, they also had EBI (Electronic Bottle Inspection) that aimed to detect and inspect the quality and appropriateness of bottles that were going to use, will be explained in the next section.

- Quality Management Practices in PT. Coca-Cola Bottling Indonesia

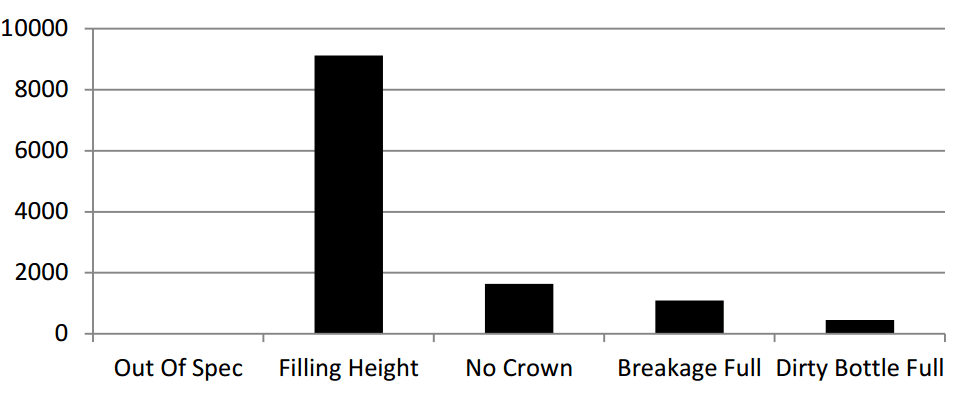

Overall, quality management of Coca-Cola Company are done by Pareto Chart and Cause-Effect Diagram or Fish-bone Chart as the tools. By using Pareto Chart, Coca-Cola Company can sort and determine majority defect of Coca-Cola, and also determine the factors of defect that’ll be analysed later. They can fix their majority defects then so that it won’t intrusive the quality of Coca-Cola itself. The highest chart in Pareto Chart shows the majority defects occur, and result of defect then will be the priority of Coca-Cola Company to be focused on. The chart below is the example of Pareto Chart used by PT. Coca-Cola Bottling Indonesia in controlling their products quality.

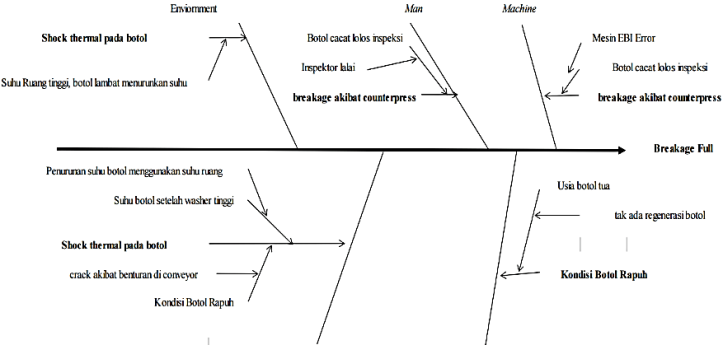

By using Cause-Effect Diagram or Fishbone Chart, Coca-Cola Company can get the information related to the factors causing the defects in production or filling or packaging process. Cause-Effect Diagram will help Coca-Cola Company in identifying the main causes of the problem and generating the ideas for the solution and also assisting in the investigation or further research of the facts. This diagram below is the example of Cause-Effect Diagram or Fishbone Chart applied by Coca-Cola Company in controlling Coca-Cola’s quality.

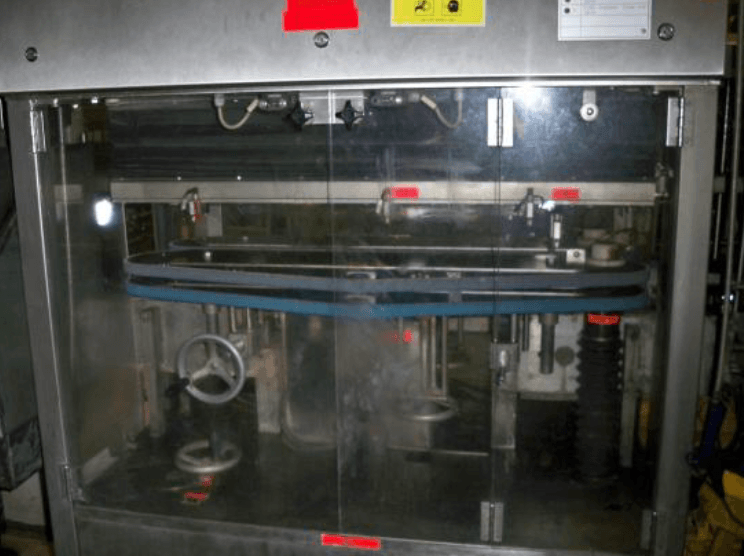

In controlling the quality of packaging or Coca-Cola’s bottle, specifically, Coca-Cola Company uses EBI (Electronic Bottle Inspection) operational system. EBI is the machine used for inspecting or detecting the bottles’ quality that is going to use the package of Coca-Cola, whether the bottles are appropriate and clean enough to use. It can be said as appropriate if the bottles have been spared from residue liquid, dirt, corrosion, scuffing, breakage, blurred bottle, and so on. Basically, EBI is divided into two main parts, that are inspection unit and rejection unit. In inspection unit, the bottles will be inspected by the sensor, from detecting colour of bottle, censoring the height of the bottles whether it’s too long or too short, detecting bottles’ position (erect or fall), detecting the base of the bottles (dirty or broken or not), detecting the neck of the bottles, and detecting residue liquid. If there are deviations of quality, the sensors will send the data to computerisations programs of EBI. It will then be rejected from the machines and directed to the bottles’ tank. Through EBI, the quality of Coca-Cola’s packaging will be more secure and hygienist because it’s passed the parts of EBI that inspect and detect the quality of the bottles.

- CONCLUSION

The Coca-Cola Company as the multinational company is involved in the era where they are faced with tight competition in the market. To be able to survive in those competitions, it’s important for Coca-Cola Company, as the leader of soft drinks in the beverage industry to have good quality management. One of the most popular products of PT. Coca-Cola Company is Coca-Cola. Coca-Cola often being confronted with negative issues or problems related to its products’ quality. It covers the quality of Coca-Cola’s content and the quality of its packaging.

Related to its products’ content issues, Coca-Cola ever lost their volume sales 1% caused by the negative issues related to the content of Coca-Cola since Coca-Cola removed the content of wine, replaced the cocaine with the non-narcotic coca leaves, and also replaced the coca leaf with sugar from a chemical process known as fructose. But, Coca-Cola Company used some strategies in fighting the negative issues through some programs they create to boost active, healthy, fit and inspire a positive lifestyle, related to physical activities.

Not only Coca-Cola’s content issues, Coca-Cola often faces the problem related to its packaging quality such as breakage full, filling height, out of specification, dirty bottles, and so on and so forth. Those problems were caused by several reasons, like human negligence and also machines error. With the issues, it resuscitates Coca-Cola Company to tighter their employees’ recruitment so that they will engage qualified and responsible employees so that the problems caused by human negligence can be minimised. Also, they implement some tools in their quality management such as EBI (Electronic Bottle Inspection), Pareto Chart, and Cause-Effect Diagram or also known as Fishbone Chart.

By combining all those tools, Coca-Cola will be able to survive in the global market even in the tight competition, as long as they could provide good quality for their customers, to build a loyalty of the customers and keep their customers to switch to another brand or products.

References

Ab Wahid, R., & Corner, J. (2009). Critical SUcess Factors and Problems in ISO 9000 maintenance. U.K.: International Journal of Quality and Reliability Management.

Aized, T. (2012). Total Quality Management and SIx SIgma. Croatia: InTech.

American Society for Quality. (2005). Fishbone Diagram. Accessed by: April 17th, 2017. United States: ASQ.

Damara, R. A. (2015). IDENTIFIKASI FAKTOR FAKTOR PENYEBAB DEFECT PRODUK PT COCA-COLA BOTTLING INDONESIA SEMARANG PLANT. Surakarta: Universitas Sebelas Maret.

Heizer, J. (2016). Operations Management. Sustainability and Supply Chain Management, 12th Edition. U.S.: Pearson Education, Inc.

Iswanto, A. (2013). Aplikasi Metode Taguchi Analysis dan Failure Mode and Effect Analysis (FMEA) Untuk Perbaikan KUalitas Produk di PT. XYZ. Yogyakarta: E-Jurnal Teknik Industri.

Laksono, P. W. (2015). ANALISIS PENYEBAB DEFECT PADA PROSES PRODUKSI PT. COCA COLA AMATIL INDONESIA – CENTRAL JAVA. Surakarta: Universitas Sebelas Maret.

Maunch, P. D. (2010). Quality Management. Theory and Application. U.S.: CRC Press. Taylor and Francis Group.

Nugroho, F. A. (2006). PENGENDALIAN KUALITAS PROSES PRODUKSI MINUMAN RINGAN COCA-COLA PADA PT. COCA-COLA BOTTLING INDONESIA DI UNGARAN, JAWA TENGAH. Yogyakarta: UAJY Library.

Perzyk, M. (2007). Statistical and Visualization Data Mining Tools for Foundry Production. . Katowice: Foundry Commision of the Polish Academy of Sciences.

Public Health Infrastructure. (2008). Fishbone (Ishikawa) Diagram, Assesed by: April 17th, 2017. U.S.: PHF.

Puravankara, D. (2007). STRATEGIC ANALYSIS OF COCA-COLA COMPANY. Canada: Simon Farser University (SFU).

Rampersad, H. K. (2010). Total Quality Management, An Executive Guide to Continuous Improvement. Berlin: Heidelberg: Springer.

Sadikoglu, E. (2014). The Effects of Total Quality Management Practices on Performance and the Reasons of and the Barriers to TQM Practices in Turkey. Turkey: Hindawi Publishing Corporation.

Sidin, J. P. (2014). QUALITY MANAGEMENT IMPLEMENTATION AND QUALITY OF PRODUCTION IN MALAYSIA’S MANUFACTURING COMPANIES. Sabah, Malaysia: IMPACT: International Journal of Research in Business Management.

T, D. Y. (2013). DETEKSI KERUSAKAN BOTOL MENGGUNAKAN ELECTRONIC BOTTLE INSPECTION (EBI) DI PT. COCA-COLA BOTTLING INDONESIA (CCBI) UNIT SEMARANG. Semarang: Universitas Diponegoro.

Thank you!

LikeLike